-

What happened?

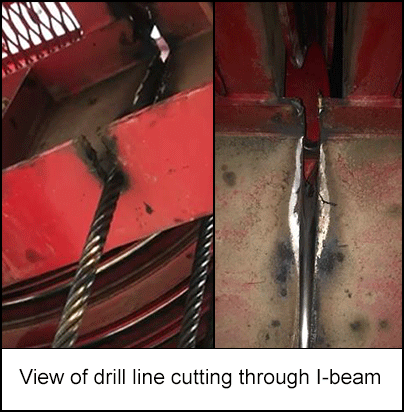

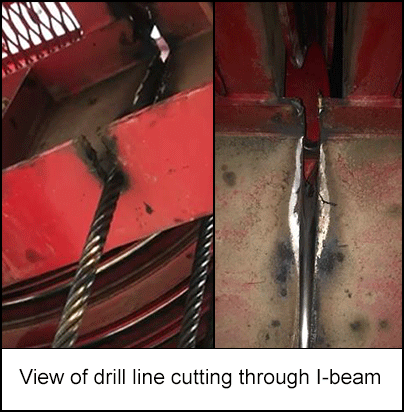

During drilling activities in a deep well, a significantly damaged I-beam located below the drilling rig crown block was identified when a melted piece of metal fell to the rig floor.

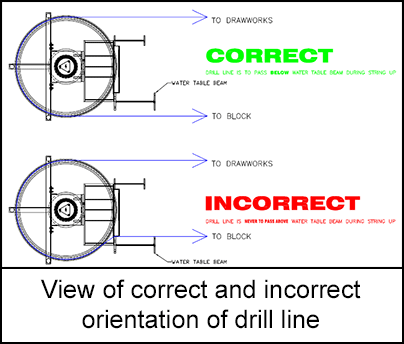

The drill line was spooled incorrectly and had cut almost completely through the I-beam, which was located below the crown block and water table.

This could have led to a serious incident.

-

Why did it happen?

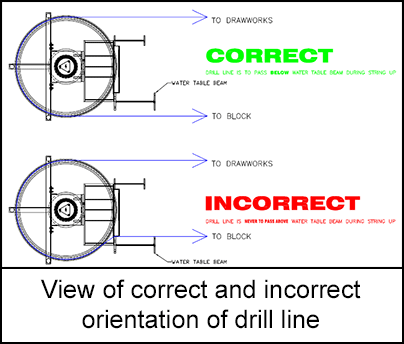

- Guards or barriers were not present to prevent the drill line from passing above the water table I-beam (from the block to the fast-line sheave) when the crown was reeved (threaded).

- The job safety analysis (JSA) and rig-specific procedures did not identify this risk or the correct routing of the drill line.

- Personnel, including the supervisor, who were all very experienced, did not identify the incorrect spooled drill line during string up (rig laid down) or subsequent dropped object inspections.

-

What did they learn?

- To prevent a serious incident in the future, evaluate water table I-beams on similar drilling rigs and install guards to prevent the drilling line from being spooled incorrectly.

- Place a decal on the water table with instructions and an arrow indicating the drill line must be spooled under the water table.

- Revise JSAs to include correct routing of the drilling line from the traveling block to the fast line sheave under the water-table I-beam and not above.

- Revise the rig-specific operating procedures to include correct routing of the drill line, including photos of correct and incorrect spooling of drill line at the water table I-beam.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During drilling activities in a deep well, a significantly damaged I-beam located below the drilling rig crown block was identified when a melted piece of metal fell to the rig floor.

The drill line was spooled incorrectly and had cut almost completely through the I-beam, which was located below the crown block and water table.

This could have led to a serious incident.

Why did it happen?

- Guards or barriers were not present to prevent the drill line from passing above the water table I-beam (from the block to the fast-line sheave) when the crown was reeved (threaded).

- The job safety analysis (JSA) and rig-specific procedures did not identify this risk or the correct routing of the drill line.

- Personnel, including the supervisor, who were all very experienced, did not identify the incorrect spooled drill line during string up (rig laid down) or subsequent dropped object inspections.

What did they learn?

- To prevent a serious incident in the future, evaluate water table I-beams on similar drilling rigs and install guards to prevent the drilling line from being spooled incorrectly.

- Place a decal on the water table with instructions and an arrow indicating the drill line must be spooled under the water table.

- Revise JSAs to include correct routing of the drilling line from the traveling block to the fast line sheave under the water-table I-beam and not above.

- Revise the rig-specific operating procedures to include correct routing of the drill line, including photos of correct and incorrect spooling of drill line at the water table I-beam.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 08/04/23

1622 Views

During drilling activities in a deep well, a significantly damaged I-beam located below the drilling rig crown block was identified when a melted piece of metal fell to the rig floor. The drill line was spooled incorrectly and had cut almost completely through the I-beam, which was located below the crown block and water table. This could have led to a serious incident.

Original material courtesy of Energy Safety Canada

Other resources:

Life Saving Rules

Dropped Objects Program

Energy Safety Canada partnered with DROPS (DropsOnline.org) to establish a Canadian chapter. To become a member, review the Terms of Reference on the Canadian Chapter DROPS website and send an email to express your interest.