-

What happened?

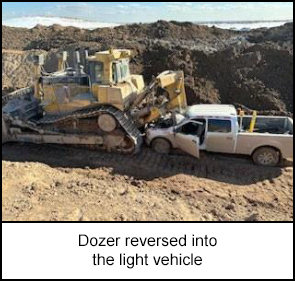

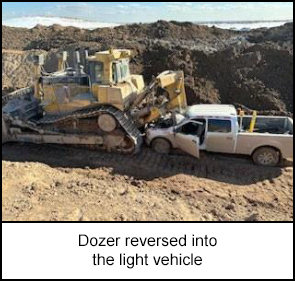

A light vehicle (LV) entered an active work area where a dozer was back blading in a narrow corridor.

The LV operator called the dozer operator via radio but received no response, however continued to approach.

The dozer reversed, causing major damage to the LV.

The LV operator successfully exited the LV and signalled the dozer operator to stop.

There were no injuries.

-

Why did it happen?

The LV operator was within ~20 metres (66 feet) behind the dozer and not seen when the dozer started to reverse.

The only direction to approach was within a blind spot at the back of the dozer.

The narrow corridor was an unidentified hazard. No barricades were in place to keep workers or LVs out of this work area.

LV operator did not follow Safe Approach standard of 50/10 rule. This means ground personnel must make eye contact with an equipment operator and wait for positive confirmation by the operator when 50 metres from the equipment.

-

What did they learn?

Regularly assess the strength of safeguards to ensure they are properly implemented and capable of helping to fail safely in the event of human error.

Work areas and access evolve throughout a project, so ensure ongoing assessment of workplace set-up, hazards and associated safeguards.

Use hard barriers where possible to separate LVs from heavy equipment in active work areas.

Regular practice and field verification of Safe Approach standards (or local relevant standards) are necessary to ensure understanding and compliance.

-

Ask yourself or your crew

How could something like this happen at our site?

How do our crew members communicate vehicle location and intended vehicle movements? Are we consistently using clear signals of intention?

What action(s) can be taken if primary communication systems are ineffective or fail? Do we have backup systems in place?

How can changing site conditions and constraints affect vehicle operation procedures? How often do we reassess these procedures?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A light vehicle (LV) entered an active work area where a dozer was back blading in a narrow corridor.

The LV operator called the dozer operator via radio but received no response, however continued to approach.

The dozer reversed, causing major damage to the LV.

The LV operator successfully exited the LV and signalled the dozer operator to stop.

There were no injuries.

Why did it happen?

The LV operator was within ~20 metres (66 feet) behind the dozer and not seen when the dozer started to reverse.

The only direction to approach was within a blind spot at the back of the dozer.

The narrow corridor was an unidentified hazard. No barricades were in place to keep workers or LVs out of this work area.

LV operator did not follow Safe Approach standard of 50/10 rule. This means ground personnel must make eye contact with an equipment operator and wait for positive confirmation by the operator when 50 metres from the equipment.

What did they learn?

Regularly assess the strength of safeguards to ensure they are properly implemented and capable of helping to fail safely in the event of human error.

Work areas and access evolve throughout a project, so ensure ongoing assessment of workplace set-up, hazards and associated safeguards.

Use hard barriers where possible to separate LVs from heavy equipment in active work areas.

Regular practice and field verification of Safe Approach standards (or local relevant standards) are necessary to ensure understanding and compliance.

Ask yourself or your crew

How could something like this happen at our site?

How do our crew members communicate vehicle location and intended vehicle movements? Are we consistently using clear signals of intention?

What action(s) can be taken if primary communication systems are ineffective or fail? Do we have backup systems in place?

How can changing site conditions and constraints affect vehicle operation procedures? How often do we reassess these procedures?

A light vehicle entered an active work area and was damaged by a reversing dozer, but the operator safely exited without injury. The incident occurred due to the vehicle being in the dozer's blind spot and the lack of barricades in the narrow corridor.

Original material courtesy of Energy Safety Canada