-

What happened?

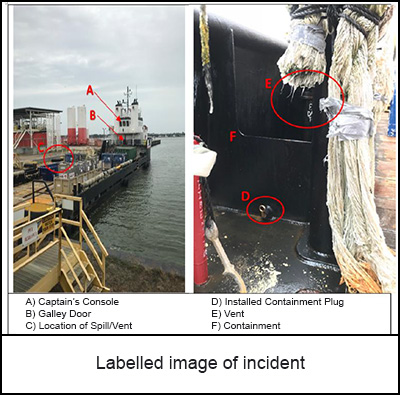

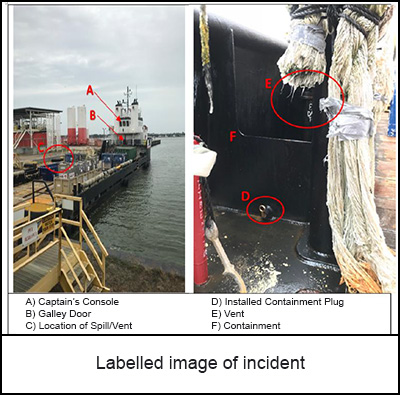

The officer of the watch (OOW) was proceeding to transfer fuel to the day-tank. While walking from the starboard fuel manifold to the port day-tank, he caught his foot on the hoses he had been using for cleaning and slipped.

He went to the bridge to check up on himself and report the accident, but he forgot to stop the transfer pump before going up there. When he realised that he had left the pump running, he went back to the engine room and shut it off.

Around 90 gallons (409 litres) in total of diesel got spilled, and approximately half of that total reached the sea.

-

Why did it happen?

Pumping operations were left unattended.

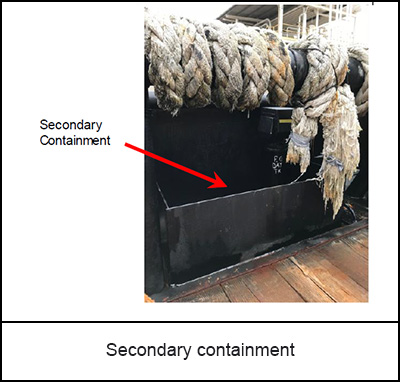

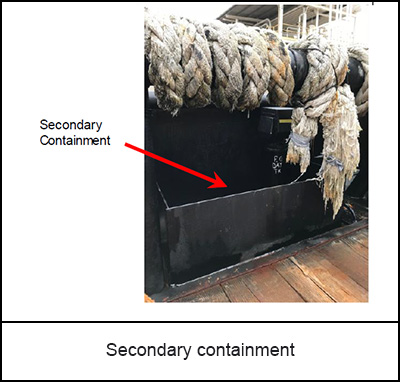

The scup plug was not installed before the transfer.

Multiple unfinished work tasks led to the slipping hazard.

-

What did they learn?

Make sure pumping operations are not left unattended.

Workers should perform one task at a time to prevent potential hazards from carrying over to the next task.

Verify integrity of secondary containment (in this case scup plug) before fuel transfer operations.

Make calculation prior to refuelling to determine the time required to refuel the day-tank.

-

Ask yourself or your crew

How can something like this happen here?

What steps do you take to verify the integrity of secondary containment?

How do we ensure that everyone understands the importance of finishing one task before moving on to the next?

What is your role in ensuring that no pumping operations are left unattended?

What measures do we have in place to ensure refuelling operations are carried out safely? What else can we do to enhance safety measures on our site?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

The officer of the watch (OOW) was proceeding to transfer fuel to the day-tank. While walking from the starboard fuel manifold to the port day-tank, he caught his foot on the hoses he had been using for cleaning and slipped.

He went to the bridge to check up on himself and report the accident, but he forgot to stop the transfer pump before going up there. When he realised that he had left the pump running, he went back to the engine room and shut it off.

Around 90 gallons (409 litres) in total of diesel got spilled, and approximately half of that total reached the sea.

Why did it happen?

Pumping operations were left unattended.

The scup plug was not installed before the transfer.

Multiple unfinished work tasks led to the slipping hazard.

What did they learn?

Make sure pumping operations are not left unattended.

Workers should perform one task at a time to prevent potential hazards from carrying over to the next task.

Verify integrity of secondary containment (in this case scup plug) before fuel transfer operations.

Make calculation prior to refuelling to determine the time required to refuel the day-tank.

Ask yourself or your crew

How can something like this happen here?

What steps do you take to verify the integrity of secondary containment?

How do we ensure that everyone understands the importance of finishing one task before moving on to the next?

What is your role in ensuring that no pumping operations are left unattended?

What measures do we have in place to ensure refuelling operations are carried out safely? What else can we do to enhance safety measures on our site?

Diesel overfilled and spilled into the water while a day-tank was being refuelled. Around 90 gallons (409 litres) total of diesel spilled, and approximately half of that reached the sea.