-

What happened?

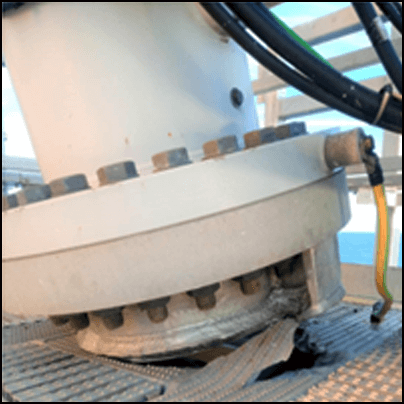

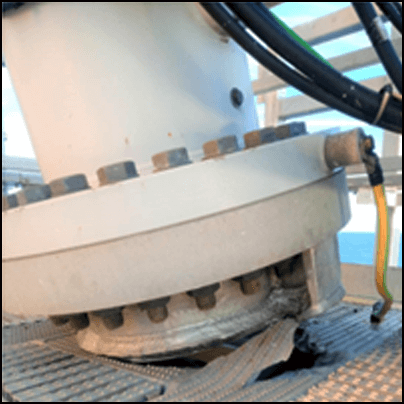

During a routine visit, it was observed that a davit crane foundation on the external working platform of a turbine had failed and became tilted towards the tower structure.

The technicians temporarily secured the failed davit crane. All lifting operations were stopped on site.

The incident was reported under local legislation requirements, and an internal investigation was conducted. A notice was issued to mariners.

An inspection was carried out on the remaining turbines which revealed cracks on further seven davit crane foundations.

The incident caused no injuries. The implementation of safety measures on site resulted in no personnel being exposed to risk .

-

Why did it happen?

Lack of understanding of the interaction between davit crane and crane foundations when subject to the cyclic movement of the turbine on a floating wind turbine generator.

The davit crane foundation failed due to poor design, missing realistic load assumptions, then also ultimate limit state (ULS) and fatigue limit state (FLS) calculations were not performed as required.

The inherent poor design was further weakened by changes during fabrication which contributed to an accelerated fatigue failure. These changes were not performed in accordance with management of change process.

Inadequate inspection of the crane foundation - a low-level third-party verification was assigned instead of a high-level inspection of the crane, foundation and associated parts of the external platform.

-

What did they learn?

Ultimate limit state (ULS) and fatigue limit state (FLS) calculations should be performed according to requirements and standards.

Management of change procedures should be followed when design or fabrication are changed.

Interface between crane and lifting discipline and structural discipline should be well defined.

Third-party verification shall be at high level for crane foundations and associated parts of the external platform, as well as for the crane itself.

Maintenance plan and inspection frequency should be thoroughly assessed for a floating turbine.

-

Ask yourself or your crew

How can something similar happen here? What would the consequences be?

What steps should we follow if a davit crane foundation is spotted with cracks? How do we communicate this risk?

How do we verify that all load and fatigue calculations are performed correctly, and that mitigation measures are in place?

How can we improve our current processes?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a routine visit, it was observed that a davit crane foundation on the external working platform of a turbine had failed and became tilted towards the tower structure.

The technicians temporarily secured the failed davit crane. All lifting operations were stopped on site.

The incident was reported under local legislation requirements, and an internal investigation was conducted. A notice was issued to mariners.

An inspection was carried out on the remaining turbines which revealed cracks on further seven davit crane foundations.

The incident caused no injuries. The implementation of safety measures on site resulted in no personnel being exposed to risk .

Why did it happen?

Lack of understanding of the interaction between davit crane and crane foundations when subject to the cyclic movement of the turbine on a floating wind turbine generator.

The davit crane foundation failed due to poor design, missing realistic load assumptions, then also ultimate limit state (ULS) and fatigue limit state (FLS) calculations were not performed as required.

The inherent poor design was further weakened by changes during fabrication which contributed to an accelerated fatigue failure. These changes were not performed in accordance with management of change process.

Inadequate inspection of the crane foundation - a low-level third-party verification was assigned instead of a high-level inspection of the crane, foundation and associated parts of the external platform.

What did they learn?

Ultimate limit state (ULS) and fatigue limit state (FLS) calculations should be performed according to requirements and standards.

Management of change procedures should be followed when design or fabrication are changed.

Interface between crane and lifting discipline and structural discipline should be well defined.

Third-party verification shall be at high level for crane foundations and associated parts of the external platform, as well as for the crane itself.

Maintenance plan and inspection frequency should be thoroughly assessed for a floating turbine.

Ask yourself or your crew

How can something similar happen here? What would the consequences be?

What steps should we follow if a davit crane foundation is spotted with cracks? How do we communicate this risk?

How do we verify that all load and fatigue calculations are performed correctly, and that mitigation measures are in place?

How can we improve our current processes?

A davit crane foundation on the external working platform of a turbine had failed, and became tilted towards the tower structure. The main underlying cause was a lack of understanding of the interaction between davit crane and crane foundations when subject to the cyclic movement of the turbine on a floating wind turbine.