-

What happened?

A two person rope access team were deployed for blade inspections at a site.

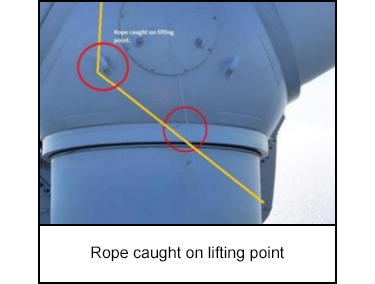

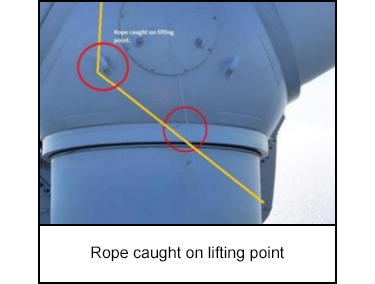

Technician A deployed two ropes over the nacelle, but technician B, believing they had become tangled, could not retrieve the ends of the ropes and tie them off properly.

Rather than retrieving the ropes for redeployment, it was decided that putting weight on the ropes would lead them to untangle on their own.

Wind speed and direction changed, so it was decided that work would stop, however due to the tangle, the technicians could not descend.

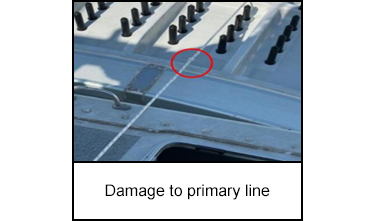

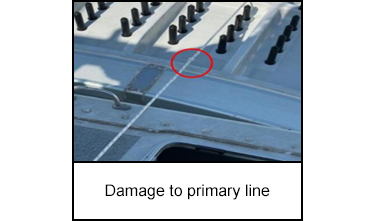

A third technician was called in to help and after the team had fully descended, it was discovered that the primary line had been damaged.

-

Why did it happen?

When the ends of the rope were tangled and unable to be tied off, works should have stopped and the ropes should have been retrieved.

If this had been carried out correctly, the technicians would have been able to descend correctly and without the external help.

-

What did they learn?

The wind turbine nacelle required yawing while ropes were in situ because of the change in wind speed/direction.

No edge protection had been installed where the ropes moved across edges just in case of unforeseen movement.

No work stop authority was exercised when the winds picked up.

No advice was given by superiors in case of a deviation from the original procedure.

-

Ask yourself or your crew

Are you happy to stop work if situations change?

Is the correct protective equipment in place in case of a changing scenario?

Are workers aware of any procedural changes for the task in case of a deviation?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A two person rope access team were deployed for blade inspections at a site.

Technician A deployed two ropes over the nacelle, but technician B, believing they had become tangled, could not retrieve the ends of the ropes and tie them off properly.

Rather than retrieving the ropes for redeployment, it was decided that putting weight on the ropes would lead them to untangle on their own.

Wind speed and direction changed, so it was decided that work would stop, however due to the tangle, the technicians could not descend.

A third technician was called in to help and after the team had fully descended, it was discovered that the primary line had been damaged.

Why did it happen?

When the ends of the rope were tangled and unable to be tied off, works should have stopped and the ropes should have been retrieved.

If this had been carried out correctly, the technicians would have been able to descend correctly and without the external help.

What did they learn?

The wind turbine nacelle required yawing while ropes were in situ because of the change in wind speed/direction.

No edge protection had been installed where the ropes moved across edges just in case of unforeseen movement.

No work stop authority was exercised when the winds picked up.

No advice was given by superiors in case of a deviation from the original procedure.

Ask yourself or your crew

Are you happy to stop work if situations change?

Is the correct protective equipment in place in case of a changing scenario?

Are workers aware of any procedural changes for the task in case of a deviation?

A rope access team couldn’t descend due to tangled ropes. A third tech assisted, and later damage to the primary line was found after descent.