-

What happened?

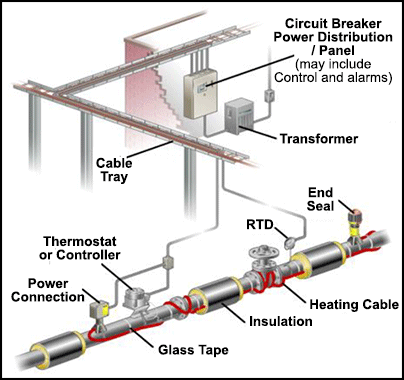

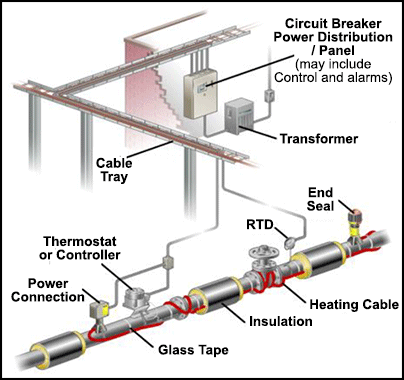

During seasonal electric heat trace (EHT) set point adjustments, four critical EHT circuits did not power on in the hydrocarbon recovery unit. The issue was identified and corrected by the following day.

Low temperature alarms for critical EHT circuits effectively alerted operations to the offline hydrocarbon recovery unit circuits.

Cross functional response team from operations, maintenance, and technical responded and promptly assessed the risk and developed an action plan.

All impacted circuits were identified and safely restarted within 24 hours.

Release process safety scenario awareness enabled an understanding of freeze and split risks, which contributed to an effective response.

There was no piping freezing or loss of containment; however, there was potential for flammable hydrocarbon release.

-

Why did it happen?

Having a less than adequate EHT system condition reporting tool resulted in ineffective repair responses for some types of EHT circuit deficiencies.

Having a less than adequate management of change for seasonal EHT set point adjustment process led to incorrect low set points being applied to 165 EHT circuits (including four critical circuits in hydrocarbon recovery unit).

-

What did they learn?

Ensure the EHT system reporting tool is up to date to improve the presentation of the EHT circuit status that requires repair.

Formalise the management of change (MOC) process for seasonal EHT set point adjustments, including procedures for field implementation.

Ensure reliable documentation of tracking/managing EHT set points.

-

Ask yourself or your crew

How are we ensuring that changes to critical systems, such as electric heat trace (EHT), are managed according to the appropriate processes?

To what extent is the management of change process being applied to all third-party managed critical systems, including EHT?

What steps could we take to improve the visibility of non-functional critical EHT circuits within our organisation?

Do we have a centralised repository for documentation concerning critical systems, particularly managed by the owner, and how effectively is it maintained?

What mechanisms are in place to conduct periodic assessments on critical systems to ensure their accuracy and reliability? What else could we implement?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During seasonal electric heat trace (EHT) set point adjustments, four critical EHT circuits did not power on in the hydrocarbon recovery unit. The issue was identified and corrected by the following day.

Low temperature alarms for critical EHT circuits effectively alerted operations to the offline hydrocarbon recovery unit circuits.

Cross functional response team from operations, maintenance, and technical responded and promptly assessed the risk and developed an action plan.

All impacted circuits were identified and safely restarted within 24 hours.

Release process safety scenario awareness enabled an understanding of freeze and split risks, which contributed to an effective response.

There was no piping freezing or loss of containment; however, there was potential for flammable hydrocarbon release.

Why did it happen?

Having a less than adequate EHT system condition reporting tool resulted in ineffective repair responses for some types of EHT circuit deficiencies.

Having a less than adequate management of change for seasonal EHT set point adjustment process led to incorrect low set points being applied to 165 EHT circuits (including four critical circuits in hydrocarbon recovery unit).

What did they learn?

Ensure the EHT system reporting tool is up to date to improve the presentation of the EHT circuit status that requires repair.

Formalise the management of change (MOC) process for seasonal EHT set point adjustments, including procedures for field implementation.

Ensure reliable documentation of tracking/managing EHT set points.

Ask yourself or your crew

How are we ensuring that changes to critical systems, such as electric heat trace (EHT), are managed according to the appropriate processes?

To what extent is the management of change process being applied to all third-party managed critical systems, including EHT?

What steps could we take to improve the visibility of non-functional critical EHT circuits within our organisation?

Do we have a centralised repository for documentation concerning critical systems, particularly managed by the owner, and how effectively is it maintained?

What mechanisms are in place to conduct periodic assessments on critical systems to ensure their accuracy and reliability? What else could we implement?

During seasonal electric heat trace (EHT) set point adjustments, four critical EHT circuits did not power on in the hydrocarbon recovery unit. All impacted circuits were identified and safely restarted within 24 hours.