-

What happened?

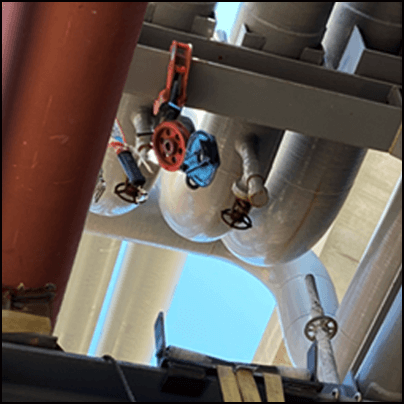

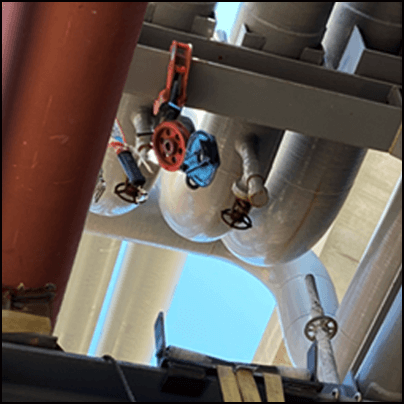

Manual lifting tools were used to lift a 12” pipe from grade to the first level of a pipe rack. Wire rope and pass-through pulleys were attached to the upper beams of the pipe rack (see images).

The worker was on a scaffold while the pipe was being lifted.

The wire rope around a pulley became disengaged and the pipe dropped. The wire rope struck the contractor causing injury.

The contractor received immediate medical treatment and was transported to the hospital. He passed away from the injuries a few hours later.

-

Why did it happen?

The pulley block failed during the manual lift of a section of pipe to the pipe rack. The key causal factors that led to the incident were:

- The 7-type latch holding the pulley block side door in-place was not closed and the door opened, likely during preparation for the lift, or at the start of the lift. This resulted in excessive load on one side of the pulley block during the lift, leading to its failure and release of the cable under load.

- The worker entered the line of fire.

Contributory factors:

- Inadequate pre-use checks of equipment by the contractor.

Human performance factors potentially affecting correct installation of the pulley block and safe execution of the lift:

- The contractor work crew was interrupted for a short break part way through the lift.

- The crew lead left the lift at the break and did not return. (It is not a legal requirement for him to stay during the lift).

- Indications of weaknesses in conformance with contractor company’s own manual lifting practice by the contractor company work crew.

Incomplete task by contractor company worker that mounted the pulley – they passed the steel cable but did not secure the side door.

-

You may wish to consider the following points when assessing your mechanical lifting processes.

Please form your own judgment and seek your independent training, where appropriate.

SAFE MECHANICAL LIFTING

- Ensure that lifting operations are being planned and performed by competent personnel using certified equipment.

- Ensure that equipment and loads are inspected prior to use and are fit for purpose.

- Adequate risk assessments of the lifting operation should be conducted prior to initiating the job.

- To protect people around suspended loads and any mechanical lifting operation, consider controlling access through physical barriers and exclusion zones.

- Consider whether personnel are exposed to danger by being under a suspended load.

SNATCH BLOCK PULLEYS

The following generic guidance is extracted from the guidance document in reference section below and is relevant to the use of all snatch block pulleys:

- Do not use snatch blocks without training

- Inform yourself on safe use instructions

- Comply with local regulations

- Always know applied lift system load

- Do not use a snatch block without a legible product identifier

- Never overload a snatch block

- Always rig a snatch block correctly

- Never use a worn-out or damaged snatch block

- Never use a snatch block in extreme temperatures

- Never use a snatch block in alkaline acidic conditions

LINE OF FIRE

Line of fire relates to struck-by and caught in-between hazards such as moving equipment and vehicles, stored pressure, and lines under tension for example around use of lifting devices / pulleys, and these are not always obvious or constant and can be introduced as the task progresses. At all times, surroundings should be continuously monitored to assure employees are not positioned in the line of fire.

- Positioning can help to avoid contact with moving equipment and vehicles, sources of energy, and dropped objects. Consider whether you or other personnel are exposed to danger by being under a suspended load.

- Ensure that exclusion zones and barriers are established.

If the job conditions change, stop the work, and assess the risks.

-

Some questions you may Ask Yourself or Your Team

How can we prevent something like this from happening here?

Did you know that pulley blocks with side doors can fail at low loadings if the door is not securely closed and latched? What other similar limitations are you aware of for this job?

Consider all equipment under tension such as the load, accessories and fix points that store energy.

- Have you identified all line of fire risks?

- What measures do you have in place to mitigate the risks?

Do you have a standard that defines:

- how mechanical lifts are conducted?

- minimum requirements for lifting activities?

- Pre-lift checks on equipment and safety devices?

What should you do if you don’t have these standards?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Manual lifting tools were used to lift a 12” pipe from grade to the first level of a pipe rack. Wire rope and pass-through pulleys were attached to the upper beams of the pipe rack (see images).

The worker was on a scaffold while the pipe was being lifted.

The wire rope around a pulley became disengaged and the pipe dropped. The wire rope struck the contractor causing injury.

The contractor received immediate medical treatment and was transported to the hospital. He passed away from the injuries a few hours later.

Why did it happen?

The pulley block failed during the manual lift of a section of pipe to the pipe rack. The key causal factors that led to the incident were:

- The 7-type latch holding the pulley block side door in-place was not closed and the door opened, likely during preparation for the lift, or at the start of the lift. This resulted in excessive load on one side of the pulley block during the lift, leading to its failure and release of the cable under load.

- The worker entered the line of fire.

Contributory factors:

- Inadequate pre-use checks of equipment by the contractor.

Human performance factors potentially affecting correct installation of the pulley block and safe execution of the lift:

- The contractor work crew was interrupted for a short break part way through the lift.

- The crew lead left the lift at the break and did not return. (It is not a legal requirement for him to stay during the lift).

- Indications of weaknesses in conformance with contractor company’s own manual lifting practice by the contractor company work crew.

Incomplete task by contractor company worker that mounted the pulley – they passed the steel cable but did not secure the side door.

You may wish to consider the following points when assessing your mechanical lifting processes.

Please form your own judgment and seek your independent training, where appropriate.

SAFE MECHANICAL LIFTING

- Ensure that lifting operations are being planned and performed by competent personnel using certified equipment.

- Ensure that equipment and loads are inspected prior to use and are fit for purpose.

- Adequate risk assessments of the lifting operation should be conducted prior to initiating the job.

- To protect people around suspended loads and any mechanical lifting operation, consider controlling access through physical barriers and exclusion zones.

- Consider whether personnel are exposed to danger by being under a suspended load.

SNATCH BLOCK PULLEYS

The following generic guidance is extracted from the guidance document in reference section below and is relevant to the use of all snatch block pulleys:

- Do not use snatch blocks without training

- Inform yourself on safe use instructions

- Comply with local regulations

- Always know applied lift system load

- Do not use a snatch block without a legible product identifier

- Never overload a snatch block

- Always rig a snatch block correctly

- Never use a worn-out or damaged snatch block

- Never use a snatch block in extreme temperatures

- Never use a snatch block in alkaline acidic conditions

LINE OF FIRE

Line of fire relates to struck-by and caught in-between hazards such as moving equipment and vehicles, stored pressure, and lines under tension for example around use of lifting devices / pulleys, and these are not always obvious or constant and can be introduced as the task progresses. At all times, surroundings should be continuously monitored to assure employees are not positioned in the line of fire.

- Positioning can help to avoid contact with moving equipment and vehicles, sources of energy, and dropped objects. Consider whether you or other personnel are exposed to danger by being under a suspended load.

- Ensure that exclusion zones and barriers are established.

If the job conditions change, stop the work, and assess the risks.

Some questions you may Ask Yourself or Your Team

How can we prevent something like this from happening here?

Did you know that pulley blocks with side doors can fail at low loadings if the door is not securely closed and latched? What other similar limitations are you aware of for this job?

Consider all equipment under tension such as the load, accessories and fix points that store energy.

- Have you identified all line of fire risks?

- What measures do you have in place to mitigate the risks?

Do you have a standard that defines:

- how mechanical lifts are conducted?

- minimum requirements for lifting activities?

- Pre-lift checks on equipment and safety devices?

What should you do if you don’t have these standards?

A worker suffered fatal injuries during a mechanical lifting operation after a pulley block failed.