-

What happened?

A maintenance team were tasked with completing a routine level transmitter initiator test on a liquefied natural gas (LNG) storage tank.

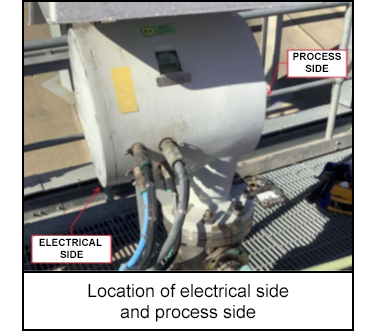

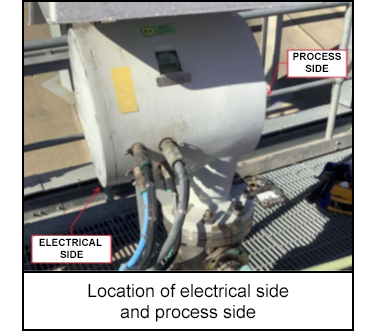

The level transmitter had two covers – one on the electrical side and one on the process side.

The maintenance activity required the cover on the electrical side to be removed.

The cover on the process side was removed instead, resulting in a loss of primary containment from the level transmitter housing.

No injuries were sustained and the release was stopped.

-

Why did it happen?

The human performance elements of the task did not deliver a ‘safe to fail’ outcome.

The task procedure was not specific to location and did not adequately identify hazards and controls.

Competency to safely execute the work (i.e. specific task / equipment) had not been verified.

-

What did they learn?

Improve identification of instrument enclosure covers and highlight the risk of removing the process side cover. This includes field labelling and improved work instructions.

Implement a process that ensures the competency of the work party is verified on the specific equipment, when assigning work tasks.

-

Ask yourself or your crew

What types of electrical equipment do you typically work on, especially those connected to gas or hydrocarbon services?

How do you distinguish between the electrical and process components of the equipment you work with?

In what ways are the electrical and process sides of equipment made distinguishable in the field and identified within your work instructions?

How do you and your work party ensure you have a 'safe to fail' condition when conducting maintenance?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A maintenance team were tasked with completing a routine level transmitter initiator test on a liquefied natural gas (LNG) storage tank.

The level transmitter had two covers – one on the electrical side and one on the process side.

The maintenance activity required the cover on the electrical side to be removed.

The cover on the process side was removed instead, resulting in a loss of primary containment from the level transmitter housing.

No injuries were sustained and the release was stopped.

Why did it happen?

The human performance elements of the task did not deliver a ‘safe to fail’ outcome.

The task procedure was not specific to location and did not adequately identify hazards and controls.

Competency to safely execute the work (i.e. specific task / equipment) had not been verified.

What did they learn?

Improve identification of instrument enclosure covers and highlight the risk of removing the process side cover. This includes field labelling and improved work instructions.

Implement a process that ensures the competency of the work party is verified on the specific equipment, when assigning work tasks.

Ask yourself or your crew

What types of electrical equipment do you typically work on, especially those connected to gas or hydrocarbon services?

How do you distinguish between the electrical and process components of the equipment you work with?

In what ways are the electrical and process sides of equipment made distinguishable in the field and identified within your work instructions?

How do you and your work party ensure you have a 'safe to fail' condition when conducting maintenance?

During a routine LNG transmitter test, the wrong cover was removed, leading to a loss of containment from the process side. The release was stopped and no injuries occurred.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/maintaining-process-equipment-loc-learning-event-bulletin