-

What happened?

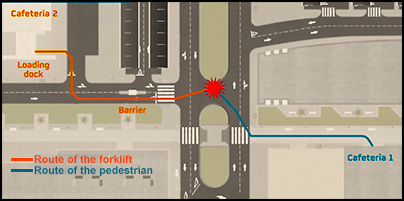

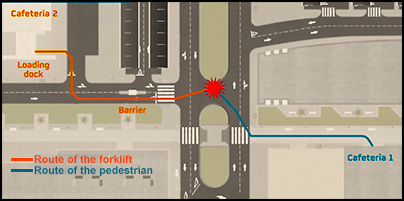

A forklift was conducting its regular waste collection routine, making its way from the loading dock of a building to the waste storage area.

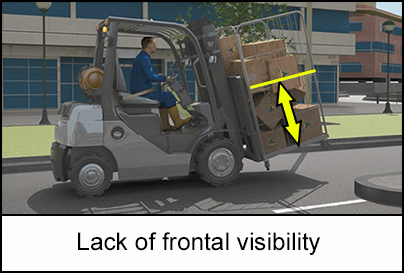

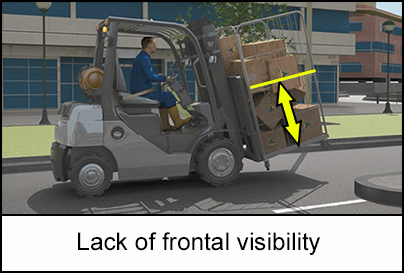

It was carrying the load at the front and the lowered fork held a metallic bin full of cardboard pieces.

As it advanced, a pedestrian crossed the road at an unmarked point whilst talking on a cell phone.

The forklift crashed into the pedestrian, who was trapped under the load. The individual involved in the accident was rescued. They suffered lesions that required a medical leave.

-

Why did it happen?

Design: There was a lack of proper road signs indicating a forklift crossing area in the facility. Not enough visibility by design/in procedure.

Training: There was a lack of perception of the risk involved by the forklift driver.

Procedures: Operational instructions for forklifts that include recommendations specific to risk activities and tasks were not available.

Communication: Lack of communicational campaigns specifically aimed at pedestrians and personnel, dealing with road safety and forklift crossing areas.

Organisation: Lack of a risk analysis that included the risks inherent to forklift driving, the working environment, and operations.

-

What did they learn?

To reduce the likelihood of an accident, good forklift design and maintenance, as well as a well-organised workplace with visibility and signage is vital.

Evaluate the installation of active safety systems, such as personnel-detection cameras with alert system software, collision detection systems, speed and load movement limiters, speed controls, etc.

Implement a practical training plan that focuses on the job position. Update the plan as:

- the risks change,

- when new lessons are learned,

- when new technologies are introduced, and when functions, work equipment, or tasks or activities change.

Include safety recommendations specific to the tasks/operations in the operational instructions e.g., speed limits, visibility, rear driving conditions or conditions required to prevent rollovers.

If different tasks are being conducted simultaneously, include instructions for safe work as well. Always be mindful of the manufacturer's safety instructions and always use the seat belt.

Inform the different contractors or pedestrians who may have access to areas where forklifts are operated of the risks linked to the movement of forklifts.

Periodically review the safety protocols and ensure they are respected. Forklifts drivers should follow all protocols, equipment manual and operational instructions and pedestrians cross at areas marked for pedestrian crossing.

Ensure that the risks stemming from the forklift, the workplace, and operations have been evaluated.

-

Ask yourself or your crew

How can we prevent something like this from happening here?

What are other risks are associated with forklift operations? How can you mitigate those risks at your work site?

What safety recommendations should be included in the operational instructions?

How can we, as a company, implement a practical training plan that focuses on the job position, and make sure pedestrians are safer from forklifts in the future?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A forklift was conducting its regular waste collection routine, making its way from the loading dock of a building to the waste storage area.

It was carrying the load at the front and the lowered fork held a metallic bin full of cardboard pieces.

As it advanced, a pedestrian crossed the road at an unmarked point whilst talking on a cell phone.

The forklift crashed into the pedestrian, who was trapped under the load. The individual involved in the accident was rescued. They suffered lesions that required a medical leave.

Why did it happen?

Design: There was a lack of proper road signs indicating a forklift crossing area in the facility. Not enough visibility by design/in procedure.

Training: There was a lack of perception of the risk involved by the forklift driver.

Procedures: Operational instructions for forklifts that include recommendations specific to risk activities and tasks were not available.

Communication: Lack of communicational campaigns specifically aimed at pedestrians and personnel, dealing with road safety and forklift crossing areas.

Organisation: Lack of a risk analysis that included the risks inherent to forklift driving, the working environment, and operations.

What did they learn?

To reduce the likelihood of an accident, good forklift design and maintenance, as well as a well-organised workplace with visibility and signage is vital.

Evaluate the installation of active safety systems, such as personnel-detection cameras with alert system software, collision detection systems, speed and load movement limiters, speed controls, etc.

Implement a practical training plan that focuses on the job position. Update the plan as:

- the risks change,

- when new lessons are learned,

- when new technologies are introduced, and when functions, work equipment, or tasks or activities change.

Include safety recommendations specific to the tasks/operations in the operational instructions e.g., speed limits, visibility, rear driving conditions or conditions required to prevent rollovers.

If different tasks are being conducted simultaneously, include instructions for safe work as well. Always be mindful of the manufacturer's safety instructions and always use the seat belt.

Inform the different contractors or pedestrians who may have access to areas where forklifts are operated of the risks linked to the movement of forklifts.

Periodically review the safety protocols and ensure they are respected. Forklifts drivers should follow all protocols, equipment manual and operational instructions and pedestrians cross at areas marked for pedestrian crossing.

Ensure that the risks stemming from the forklift, the workplace, and operations have been evaluated.

Ask yourself or your crew

How can we prevent something like this from happening here?

What are other risks are associated with forklift operations? How can you mitigate those risks at your work site?

What safety recommendations should be included in the operational instructions?

How can we, as a company, implement a practical training plan that focuses on the job position, and make sure pedestrians are safer from forklifts in the future?

A forklift was conducting its regular waste collection routine, carrying the load to the front. As it advanced, a pedestrian crossed the road. The forklift crashed into the pedestrian, who was trapped under the load. The person involved in the accident suffered lesions that required a medical leave.