-

What happened?

A Production technician performing routine rounds on a reverse osmosis (RO) water treating unit heard a very loud bang believed to come from one of the trains in an RO unit.

The technician had left the area 90 seconds prior and was 30 meters (98 feet) away.

The noise was a result of failure of a 316 stainless steel bolt on a 3-inch (7.6cm) branded pipe clamp on the high-pressure side of the RO unit.

Upon further inspection it was noted that a cable tray and polyvinyl chloride (PVC) permeate line located across a walkway were found to be damaged by the clamp when it was ejected.

The affected joint was on the feedwater side of the membrane vessels with a normal operating pressure of 50 Bar (725 psi).

-

Why did it happen?

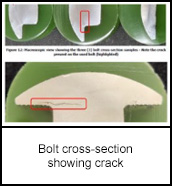

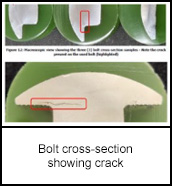

The bolt was examined at a laboratory and was found to have failed by chloride stress corrosion cracking.

Manufacturing defects were also believed to have contributed to the failure as well.

Follow-up inspection revealed an additional bolt with similar cracking that had not yet failed. These are small commodity bolts that are normally supplied with these types of pipe clamps and are commonly used in utility services and packaged equipment.

Similar failures of 316SS bolts in duplex and super duplex stainless steel clamps have been reported to the clamp manufacturer from around the globe, most commonly in their "D" type high-pressure couplings.

Because cracking has been located under the bolt head and cannot be visually detected, the manufacturer of the clamp recommends replacement of 316 SS bolts on a 5-year frequency as the primary means of mitigating risk.

They have also changed their specification to require duplex stainless-steel bolts for new RO plant applications.

-

What did they learn?

Based on risk factors for specific facilities, sites should consider implementing the recommended replacement schedule for 316 stainless steel bolts in similar saltwater RO units.

If replacing bolts, the replacement material should be duplex or super duplex stainless steel, and in that case, no further replacement schedule is needed. Priority for replacement should be given to any connections that show obvious signs of leakage or salt deposits, as the bolts in these connections would have a higher likelihood of cracking.

-

Ask yourself or your crew

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk of this happening here?

How do we assess the condition of bolts and fittings in high-pressure systems?

How do we prioritise inspections and replacements based on risk indicators like leakage or salt deposits?

How do we ensure that hidden failure modes, like sub-head cracking, are accounted for in our maintenance plans?

What improvements or changes should we make?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A Production technician performing routine rounds on a reverse osmosis (RO) water treating unit heard a very loud bang believed to come from one of the trains in an RO unit.

The technician had left the area 90 seconds prior and was 30 meters (98 feet) away.

The noise was a result of failure of a 316 stainless steel bolt on a 3-inch (7.6cm) branded pipe clamp on the high-pressure side of the RO unit.

Upon further inspection it was noted that a cable tray and polyvinyl chloride (PVC) permeate line located across a walkway were found to be damaged by the clamp when it was ejected.

The affected joint was on the feedwater side of the membrane vessels with a normal operating pressure of 50 Bar (725 psi).

Why did it happen?

The bolt was examined at a laboratory and was found to have failed by chloride stress corrosion cracking.

Manufacturing defects were also believed to have contributed to the failure as well.

Follow-up inspection revealed an additional bolt with similar cracking that had not yet failed. These are small commodity bolts that are normally supplied with these types of pipe clamps and are commonly used in utility services and packaged equipment.

Similar failures of 316SS bolts in duplex and super duplex stainless steel clamps have been reported to the clamp manufacturer from around the globe, most commonly in their "D" type high-pressure couplings.

Because cracking has been located under the bolt head and cannot be visually detected, the manufacturer of the clamp recommends replacement of 316 SS bolts on a 5-year frequency as the primary means of mitigating risk.

They have also changed their specification to require duplex stainless-steel bolts for new RO plant applications.

What did they learn?

Based on risk factors for specific facilities, sites should consider implementing the recommended replacement schedule for 316 stainless steel bolts in similar saltwater RO units.

If replacing bolts, the replacement material should be duplex or super duplex stainless steel, and in that case, no further replacement schedule is needed. Priority for replacement should be given to any connections that show obvious signs of leakage or salt deposits, as the bolts in these connections would have a higher likelihood of cracking.

Ask yourself or your crew

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk of this happening here?

How do we assess the condition of bolts and fittings in high-pressure systems?

How do we prioritise inspections and replacements based on risk indicators like leakage or salt deposits?

How do we ensure that hidden failure modes, like sub-head cracking, are accounted for in our maintenance plans?

What improvements or changes should we make?

A clamp bolt failed due to chloride stress corrosion cracking, ejecting metal at high velocity. The incident highlights inspection and material selection risks.