-

What happened?

A measurement-while-drilling (MWD) tool was being hoisted with an original equipment manufacturer (OEM) lifting assembly up the v-door with a derrick full of pipe.

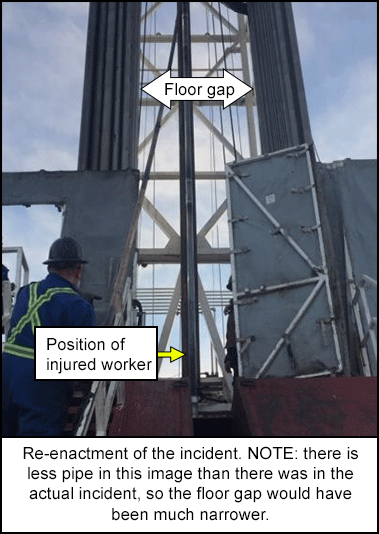

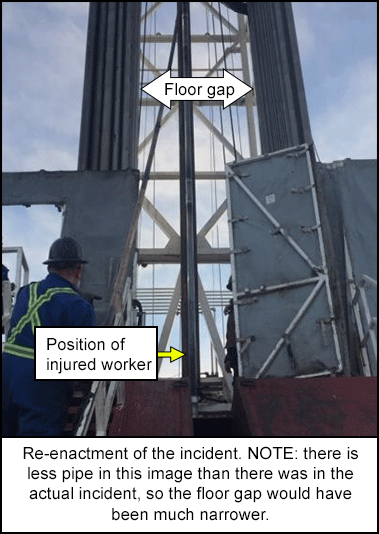

One worker on the rig floor was standing between the racked pipe to watch the tool and give instructions to the tugger (winch) operator. A second worker was guiding the tool up the stairs.

The 10m-long tool was 8m above the drill floor when it fell, grazing the first worker’s hardhat and the back of his gloved hand, resulting in a hematoma above the right eye and a bruised right hand. The second worker was narrowly missed by the falling tool.

-

Why did it happen?

Investigation findings:

- The two workers had independently inspected the tool and lifting assembly before it was picked up. They verified that the retaining pin was in place.

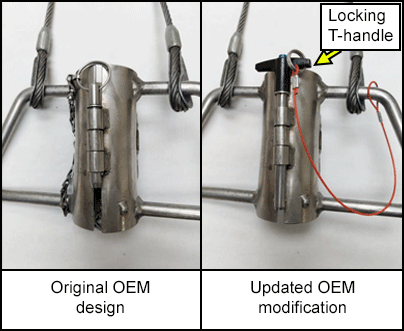

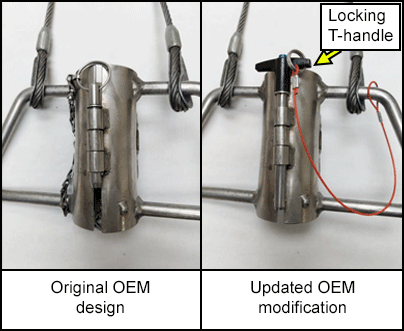

- The retaining chain of the lifting assembly snagged on the racked pipe which allowed for the pin to release from the gate, allowing the tool to fall.

- This weak point of the design was previously identified, and an improved T-locking handle push pin was available but not all field kits had received the upgrade.

- The worker on the floor was positioned to provide both verbal and visual direction to the tugger operator but was standing in the drop zone to achieve that.

- Due to potential damage to the bottom of the tool, and the skate v-door design, the second worker had to guide the MWD tool up the stairs, which was also in the drop zone.

Contributing factors:

- The OEM design was susceptible to this failure.

- The upgrade for the lifting assembly was missed on the load-out.

- Inadequate hazard assessment of the existing, older-style assembly.

- Worker was positioned in the drop zone to give verbal and visual direction to the tugger operator, rather than at the top of the stairs giving only verbal direction.

-

What did they learn?

- Assess and update all lifting assemblies with OEM-approved modification.

- Regularly audit all mechanical lifting equipment.

- Identify line of fire and drop zones when handling tools and modify work practices accordingly.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A measurement-while-drilling (MWD) tool was being hoisted with an original equipment manufacturer (OEM) lifting assembly up the v-door with a derrick full of pipe.

One worker on the rig floor was standing between the racked pipe to watch the tool and give instructions to the tugger (winch) operator. A second worker was guiding the tool up the stairs.

The 10m-long tool was 8m above the drill floor when it fell, grazing the first worker’s hardhat and the back of his gloved hand, resulting in a hematoma above the right eye and a bruised right hand. The second worker was narrowly missed by the falling tool.

Why did it happen?

Investigation findings:

- The two workers had independently inspected the tool and lifting assembly before it was picked up. They verified that the retaining pin was in place.

- The retaining chain of the lifting assembly snagged on the racked pipe which allowed for the pin to release from the gate, allowing the tool to fall.

- This weak point of the design was previously identified, and an improved T-locking handle push pin was available but not all field kits had received the upgrade.

- The worker on the floor was positioned to provide both verbal and visual direction to the tugger operator but was standing in the drop zone to achieve that.

- Due to potential damage to the bottom of the tool, and the skate v-door design, the second worker had to guide the MWD tool up the stairs, which was also in the drop zone.

Contributing factors:

- The OEM design was susceptible to this failure.

- The upgrade for the lifting assembly was missed on the load-out.

- Inadequate hazard assessment of the existing, older-style assembly.

- Worker was positioned in the drop zone to give verbal and visual direction to the tugger operator, rather than at the top of the stairs giving only verbal direction.

What did they learn?

- Assess and update all lifting assemblies with OEM-approved modification.

- Regularly audit all mechanical lifting equipment.

- Identify line of fire and drop zones when handling tools and modify work practices accordingly.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 17/04/23

1624 Views

A measurement-while-drilling (MWD) tool was being hoisted by an original equipment manufacturer (OEM) lifting assembly up the v-door with a derrick full of pipe. The long tool fell, grazing the first worker’s hardhat and the back of his gloved hand. The second worker was narrowly missed by the falling tool.

Original material courtesy of Energy Safety Canada

Other resources:

Learn more about this Life Saving Rule | Safe Mechanical Lifting