-

What happened?

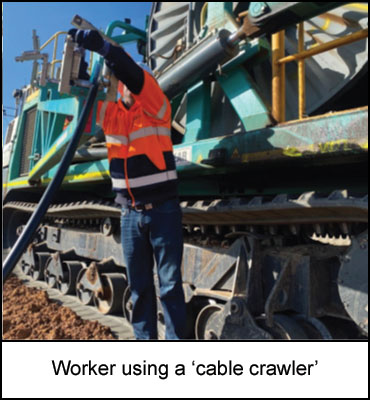

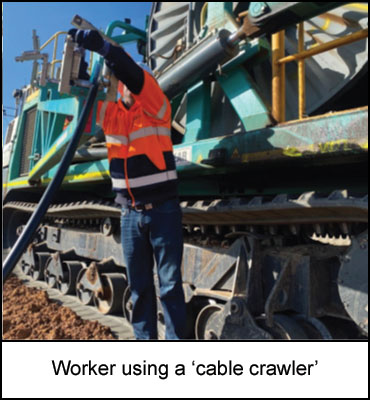

A crew was installing electrical cable in a trench using specialist equipment (a ‘cable crawler’).

As they reached the end of a cable the crew began to remove the cable drum from the rear of the crawler so that they could load a new drum.

The leading hand moved between the cable crawler and its hydraulic arm that lays the cable into the trench, to disconnect cable clips.

While this was occurring the arm was activated remotely. The leading hand was pinned between the cable crawler and its arm, resulting in multiple fractured ribs.

-

Why did it happen?

The leading hand was in the line of fire:

- Risk assessments / safe work method statement (SWMS) / job hazard analysis (JHA) identified line of fire risk.

- Signage was in place.

- Difficult to reach cable clips if not in the line of fire. Entering the line of fire to release cable clips had been normalised.

- Pre-start discussions on the day did not mention line of fire risk.

Person in control of the cable crawler operated the hydraulic arm remotely with a person in the line of fire:

- Operator was not paying full attention to the task and had no visibility of the person positioned between the cable crawler and its arm.

- Arm operated in wrong control mode. Changes to improve crawler operation had been inconsistently applied across the fleet.

-

What did they learn?

Install position limiters on hydraulics (spacer/hydraulic lock) to prevent the ram from fully closing the arm.

Install access platform to remove need to be in the line of fire to access cable clips.

Modify remote control dual activation switch to prompt deliberate decision to move from one mode to another (3 step process incorporated).

Install audible alarm and flashing lights as warning that the hydraulic arm will move.

Review design and operating instruction across the fleet to ensure consistency.

Improve processes for managing any future changes consistently across the fleet.

Ensure transition to work and step 7 processes are used to review tasks. Identify hazards associated with the work method and implement controls prior to starting work.

Reinforce leadership responsibility to visit worksites. Engage with frontline workers to identify hazards and manage risk (especially in routine operations). “Worry about the things that we’re not worried about”.

Refresh leadership commitment to verify that controls are in place and that hazards are resolved when they are identified.

-

Ask yourself or your crew

Do you work with hydraulic equipment that is operated remotely? Is it possible that you could be caught in the line of fire when operating this equipment?

Do you actively seek to identify potential line of fire risks? Do you ask why people are located in the line of fire? How do you manage these risks?

How do you report these risks when you identify them? Does your crew use step 7 processes to identify hazards associated with your work and to check that controls are in place before starting work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A crew was installing electrical cable in a trench using specialist equipment (a ‘cable crawler’).

As they reached the end of a cable the crew began to remove the cable drum from the rear of the crawler so that they could load a new drum.

The leading hand moved between the cable crawler and its hydraulic arm that lays the cable into the trench, to disconnect cable clips.

While this was occurring the arm was activated remotely. The leading hand was pinned between the cable crawler and its arm, resulting in multiple fractured ribs.

Why did it happen?

The leading hand was in the line of fire:

- Risk assessments / safe work method statement (SWMS) / job hazard analysis (JHA) identified line of fire risk.

- Signage was in place.

- Difficult to reach cable clips if not in the line of fire. Entering the line of fire to release cable clips had been normalised.

- Pre-start discussions on the day did not mention line of fire risk.

Person in control of the cable crawler operated the hydraulic arm remotely with a person in the line of fire:

- Operator was not paying full attention to the task and had no visibility of the person positioned between the cable crawler and its arm.

- Arm operated in wrong control mode. Changes to improve crawler operation had been inconsistently applied across the fleet.

What did they learn?

Install position limiters on hydraulics (spacer/hydraulic lock) to prevent the ram from fully closing the arm.

Install access platform to remove need to be in the line of fire to access cable clips.

Modify remote control dual activation switch to prompt deliberate decision to move from one mode to another (3 step process incorporated).

Install audible alarm and flashing lights as warning that the hydraulic arm will move.

Review design and operating instruction across the fleet to ensure consistency.

Improve processes for managing any future changes consistently across the fleet.

Ensure transition to work and step 7 processes are used to review tasks. Identify hazards associated with the work method and implement controls prior to starting work.

Reinforce leadership responsibility to visit worksites. Engage with frontline workers to identify hazards and manage risk (especially in routine operations). “Worry about the things that we’re not worried about”.

Refresh leadership commitment to verify that controls are in place and that hazards are resolved when they are identified.

Ask yourself or your crew

Do you work with hydraulic equipment that is operated remotely? Is it possible that you could be caught in the line of fire when operating this equipment?

Do you actively seek to identify potential line of fire risks? Do you ask why people are located in the line of fire? How do you manage these risks?

How do you report these risks when you identify them? Does your crew use step 7 processes to identify hazards associated with your work and to check that controls are in place before starting work?

While installing electrical cable, a crew member was pinned between a cable crawler and its hydraulic arm, which was activated remotely, resulting in multiple fractured ribs.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/operating-mobile-plant-person-in-line-of-fire-leb-toolbox