-

What happened?

A tank with an internal floating roof was damaged due to a pressure imbalance.

It began when the cryogenic unit shut down, causing low pressure in the system. At the same time, the flare system pressure rose to 60 psig, while the rundown line to the tank had low pressure.

This pressure difference caused gas to flow backward from the flare system through a pressure safety valve (PSV) into the tank. The resulting high pressure inside the tank caused the floating roof to tilt or sink, damaging its seal.

-

Why did it happen?

There was backflow from the flare header to the tank, resulting in overpressure.

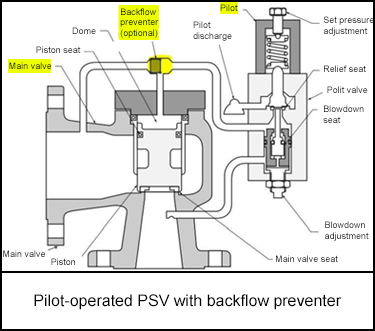

Pilot-operated PSVs on the oil run-down line were installed without back-flow preventers, which allowed back-flow during a flare event.

The relief system back pressure (flare) exceeded the process pressure (rundown line).

The pressure differential across the PSV caused sufficient upward force on the diaphragm/piston to open the valve and cause flow reversal.

-

What did they learn?

Ensure that PSV specifications and designs consider the potential for backpressure higher than inlet pressure, allowing for backflow from the flare header to the internal floating roof tanks.

- The backflow preventer allows the discharge pressure to provide a net downward force on the diaphragm or piston to keep the valve closed.

Ensure a backflow preventer is specified whenever:

- a vacuum may be present at the inlet connection due to unusual operating conditions or when a temporary vacuum may occur under start-up conditions;

- the discharge of the safety valve is connected to a downstream pressure vessel, where pressure may vary occasionally in excess of the pressure in the upstream system; and/or

- the discharge of multiple safety valves is combined into a single manifold or vent system, creating superimposed back pressures in excess of the current upstream system pressure.

-

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A tank with an internal floating roof was damaged due to a pressure imbalance.

It began when the cryogenic unit shut down, causing low pressure in the system. At the same time, the flare system pressure rose to 60 psig, while the rundown line to the tank had low pressure.

This pressure difference caused gas to flow backward from the flare system through a pressure safety valve (PSV) into the tank. The resulting high pressure inside the tank caused the floating roof to tilt or sink, damaging its seal.

Why did it happen?

There was backflow from the flare header to the tank, resulting in overpressure.

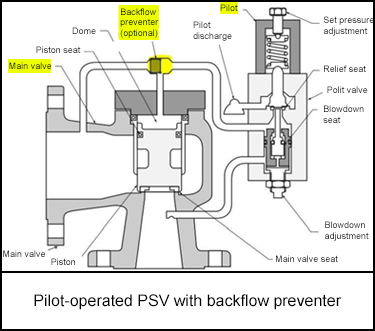

Pilot-operated PSVs on the oil run-down line were installed without back-flow preventers, which allowed back-flow during a flare event.

The relief system back pressure (flare) exceeded the process pressure (rundown line).

The pressure differential across the PSV caused sufficient upward force on the diaphragm/piston to open the valve and cause flow reversal.

What did they learn?

Ensure that PSV specifications and designs consider the potential for backpressure higher than inlet pressure, allowing for backflow from the flare header to the internal floating roof tanks.

- The backflow preventer allows the discharge pressure to provide a net downward force on the diaphragm or piston to keep the valve closed.

Ensure a backflow preventer is specified whenever:

- a vacuum may be present at the inlet connection due to unusual operating conditions or when a temporary vacuum may occur under start-up conditions;

- the discharge of the safety valve is connected to a downstream pressure vessel, where pressure may vary occasionally in excess of the pressure in the upstream system; and/or

- the discharge of multiple safety valves is combined into a single manifold or vent system, creating superimposed back pressures in excess of the current upstream system pressure.

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

Seal damage occurred on tanks with internal floating roofs due to overpressure caused by backflow from the flare system during a cryogenic unit shutdown; this happened because pilot-operated pressure safety valves (PSVs) on the rundown line lacked back-flow preventers, allowing flare header pressure to exceed process pressure and force the valves open.