-

What happened?

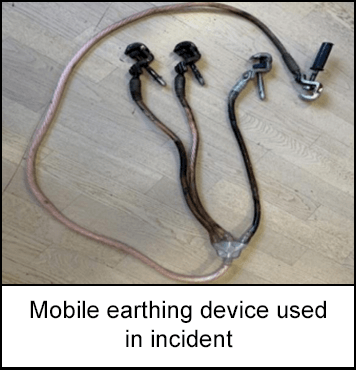

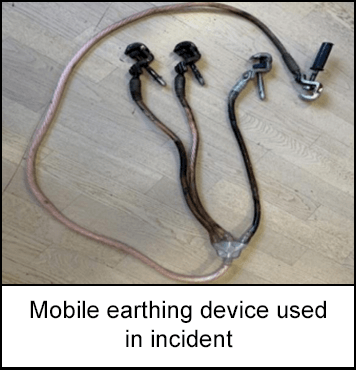

During transformer maintenance at a wind turbine, a contractor, who was an authorized person, used a mobile earthing device on the low-voltage (LV) side of the transformer to comply with safety regulations by grounding and controlling stray or fault currents.

After disconnecting from the grid, the high-voltage (HV) circuit breaker earthed the HV side of the transformer.

When the transformer was re-energized by closing the HV circuit breaker, the earthing spider on the LV side was not removed, despite being reported to the control engineer (CE).

As a result, a short circuit path was created between three phases and earth, leading to a release of hazardous energy in the form of an arc flash.

Fortunately, no injuries occurred, but the incident had the potential to cause one or more fatalities.

-

Why did it happen?

The design of the earthing spider and earthing device was inadequate.

The earthing spider, a portable primary earthing device used to secure the LV side of the transformer to earth, was not removed before re-energization, leading to the short circuit condition.

The design and attachment points (ball point connectors) of the earthing spider on the transformer LV conductors were not suitable to handle the calculated short circuit current, resulting in melting and deformation of the connectors and the subsequent arc flash.

In a properly rated earthing system, the current passing through a short circuit would have gradually increased until the high-voltage circuit breaker tripped due to overcurrent. In a well-designed system, this tripping process would have occurred without causing an arc flash.

There was a failure to rigorously implement the company's electrical safety rules, particularly regarding the switching schedule for safe work on electrical installations.

These rules included the appointment of duty holders responsible for carrying out work practices that prevent the release of hazardous energy. Unfortunately, the switching schedule was not diligently followed or executed as intended, leading to the incident.

-

What did they learn?

Implement electrical safety rules with utmost rigor.

Consider introducing 'earthing schedules' at all sites, documenting the application and removal of 'portable earthing devices' and 'fixed earthing devices' in a specific safety document that complements the main 'switching schedule.' Where this is felt to be inappropriate by the responsible authority, an equivalent level of control should be included in the ‘safe system of work’ used.

Ensure proper selection and control of contractors for safety-critical work. The remote nature of offshore activities means that the trust between control engineers and appointed persons is vital for adhering to electrical safety rules.

-

Ask yourself or your crew

How can this happen here?

How familiar are you with the company's electrical safety rules and the switching schedule for electrical installations? What should you do if you are not fully familiar with these?

Have you ever encountered situations where safety measures were not followed, and how did you address them?

In your opinion, what are the critical aspects of electrical safety during offshore activities?

What improvements or additional measures do you think can be implemented to enhance safety when working with transformers and electrical systems?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During transformer maintenance at a wind turbine, a contractor, who was an authorized person, used a mobile earthing device on the low-voltage (LV) side of the transformer to comply with safety regulations by grounding and controlling stray or fault currents.

After disconnecting from the grid, the high-voltage (HV) circuit breaker earthed the HV side of the transformer.

When the transformer was re-energized by closing the HV circuit breaker, the earthing spider on the LV side was not removed, despite being reported to the control engineer (CE).

As a result, a short circuit path was created between three phases and earth, leading to a release of hazardous energy in the form of an arc flash.

Fortunately, no injuries occurred, but the incident had the potential to cause one or more fatalities.

Why did it happen?

The design of the earthing spider and earthing device was inadequate.

The earthing spider, a portable primary earthing device used to secure the LV side of the transformer to earth, was not removed before re-energization, leading to the short circuit condition.

The design and attachment points (ball point connectors) of the earthing spider on the transformer LV conductors were not suitable to handle the calculated short circuit current, resulting in melting and deformation of the connectors and the subsequent arc flash.

In a properly rated earthing system, the current passing through a short circuit would have gradually increased until the high-voltage circuit breaker tripped due to overcurrent. In a well-designed system, this tripping process would have occurred without causing an arc flash.

There was a failure to rigorously implement the company's electrical safety rules, particularly regarding the switching schedule for safe work on electrical installations.

These rules included the appointment of duty holders responsible for carrying out work practices that prevent the release of hazardous energy. Unfortunately, the switching schedule was not diligently followed or executed as intended, leading to the incident.

What did they learn?

Implement electrical safety rules with utmost rigor.

Consider introducing 'earthing schedules' at all sites, documenting the application and removal of 'portable earthing devices' and 'fixed earthing devices' in a specific safety document that complements the main 'switching schedule.' Where this is felt to be inappropriate by the responsible authority, an equivalent level of control should be included in the ‘safe system of work’ used.

Ensure proper selection and control of contractors for safety-critical work. The remote nature of offshore activities means that the trust between control engineers and appointed persons is vital for adhering to electrical safety rules.

Ask yourself or your crew

How can this happen here?

How familiar are you with the company's electrical safety rules and the switching schedule for electrical installations? What should you do if you are not fully familiar with these?

Have you ever encountered situations where safety measures were not followed, and how did you address them?

In your opinion, what are the critical aspects of electrical safety during offshore activities?

What improvements or additional measures do you think can be implemented to enhance safety when working with transformers and electrical systems?

An arc flash occurred during transformer maintenance at a wind turbine. Fortunately, no injuries occurred, but the incident had the potential to cause one or more fatalities.