-

What happened?

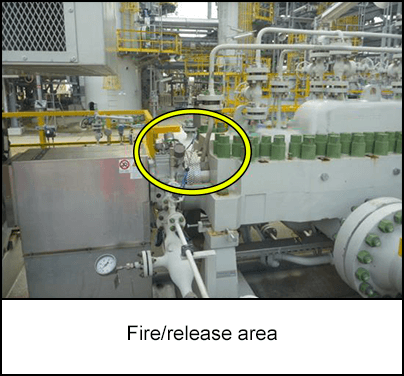

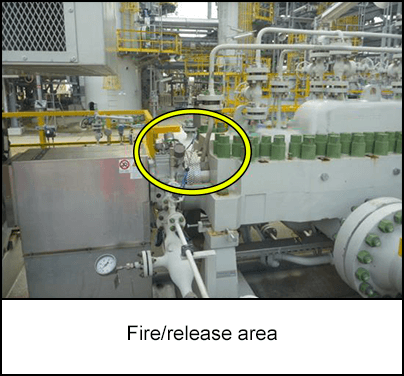

During a plant shutdown, the amine circulation pump driver failed to shut off as expected. This led to overheating and a localised fire at the drive end seal due to a lack of flow.

The fire was extinguished, and pump cooled down by applying fire water.

Approximately 80 litres (17.5 gallons) of amine were released as a result of this seal failure.

The pump motor continued to run and could not be stopped by the local start/stop station, remote control or push button at motor cubicle.

The plant followed safe work practice to disconnect the power. The motor stopped approximately 30 minutes after plant shutdown.

-

Why did it happen?

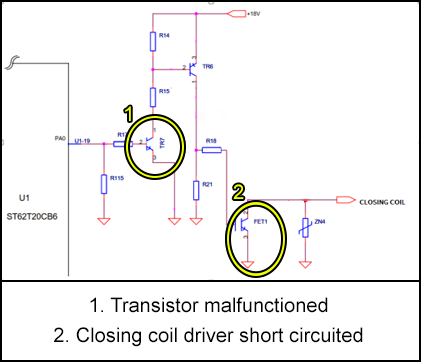

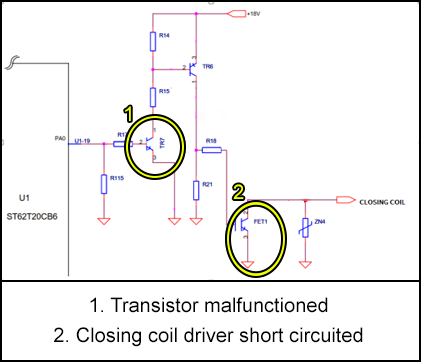

The component malfunction in the electronic drive unit card of the vacuum contactor prevented opening of the pump motor feeder contactor.

This was not initially known or detected as no diagnostic information was available to indicate the problem.

-

What did they learn?

Older versions of the electronic drive unit card in medium voltage vacuum contactors can experience unrevealed failures. Consider updating them to a current design with diagnostic features.

Install an emergency trip system independent of the electronic drive card to enhance safety during shutdown procedures.

-

Ask yourself or your crew

How can a similar incident happen here?

What steps can you take to ensure that the pump motor can be stopped promptly in case of a similar situation?

What alternative methods can be employed to shut down critical equipment in case of malfunctions?

Are there other critical components in your systems that may have unrevealed failures, and what preventive measures can be put in place to address them?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a plant shutdown, the amine circulation pump driver failed to shut off as expected. This led to overheating and a localised fire at the drive end seal due to a lack of flow.

The fire was extinguished, and pump cooled down by applying fire water.

Approximately 80 litres (17.5 gallons) of amine were released as a result of this seal failure.

The pump motor continued to run and could not be stopped by the local start/stop station, remote control or push button at motor cubicle.

The plant followed safe work practice to disconnect the power. The motor stopped approximately 30 minutes after plant shutdown.

Why did it happen?

The component malfunction in the electronic drive unit card of the vacuum contactor prevented opening of the pump motor feeder contactor.

This was not initially known or detected as no diagnostic information was available to indicate the problem.

What did they learn?

Older versions of the electronic drive unit card in medium voltage vacuum contactors can experience unrevealed failures. Consider updating them to a current design with diagnostic features.

Install an emergency trip system independent of the electronic drive card to enhance safety during shutdown procedures.

Ask yourself or your crew

How can a similar incident happen here?

What steps can you take to ensure that the pump motor can be stopped promptly in case of a similar situation?

What alternative methods can be employed to shut down critical equipment in case of malfunctions?

Are there other critical components in your systems that may have unrevealed failures, and what preventive measures can be put in place to address them?

During a plant shutdown, the amine circulation pump driver failed to shut off as expected. This led to overheating and a localised fire at the drive end seal due to a lack of flow. The fire was extinguished, and pump cooled down by applying fire water.