-

What happened?

A subcontractor was assigned a task at a wind turbine generator (WTG).

The crew transfer vessel (CTV) ferrying the technicians was pressing against the boat landing, and all four technicians climbed from the CTV to the external platform.

Technicians 1 & 2 supervised the transfer of lifting bags from the CTV to the WTG.

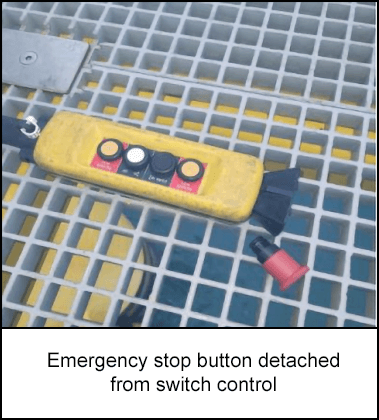

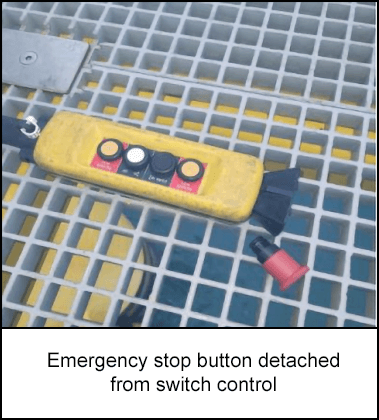

During the equipment transfer, the emergency stop button detached, causing the lift to stop.

While attempting to reactivate the emergency stop, the brake release was accidentally triggered, leading to three lift bags falling into the sea.

The bags were later retrieved by the CTV.

-

Why did it happen?

The absence of lifting information in the risk assessment and method statement (RAMS) resulted in a lack of focus on the lifting operation.

There was no established policy for lockout/tagout (LOTO) procedures.

Technicians had not received training on how and when to implement LOTO.

A clear procedure for ongoing training of long-term subcontractors was lacking.

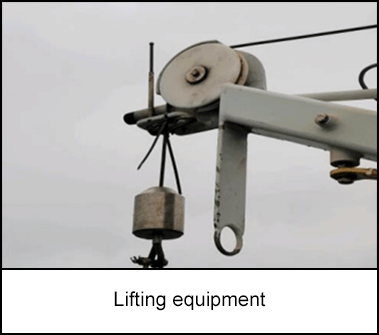

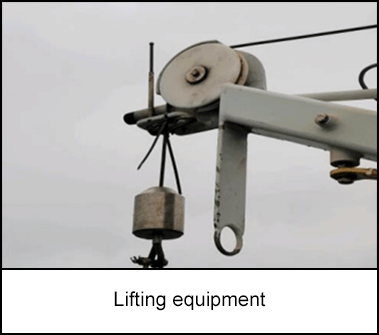

The absence of a physical pre-job briefing/task-based training meant that technicians were unaware of the limitations of the davit crane.

-

What did they learn?

Implement regular and ongoing training programs for both subcontractors and in-house employees, recognising that many subcontractors have long-term engagements.

Prioritise clear and open communication channels to facilitate information sharing and prevent misunderstandings.

Recognise the significance of every component within an operation and ensure that all aspects are given due attention and consideration.

Enhance procedures for collaborating with subcontractors to ensure effective coordination and execution of tasks.

-

Ask yourself or your crew

What was the potential severity of this incident?

How can something like this happen here?

How can we ensure that all team members fully understand and implement lockout/tagout procedures in our work environment?

What steps can we take to enhance the safety of lifting operations in offshore wind operations?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A subcontractor was assigned a task at a wind turbine generator (WTG).

The crew transfer vessel (CTV) ferrying the technicians was pressing against the boat landing, and all four technicians climbed from the CTV to the external platform.

Technicians 1 & 2 supervised the transfer of lifting bags from the CTV to the WTG.

During the equipment transfer, the emergency stop button detached, causing the lift to stop.

While attempting to reactivate the emergency stop, the brake release was accidentally triggered, leading to three lift bags falling into the sea.

The bags were later retrieved by the CTV.

Why did it happen?

The absence of lifting information in the risk assessment and method statement (RAMS) resulted in a lack of focus on the lifting operation.

There was no established policy for lockout/tagout (LOTO) procedures.

Technicians had not received training on how and when to implement LOTO.

A clear procedure for ongoing training of long-term subcontractors was lacking.

The absence of a physical pre-job briefing/task-based training meant that technicians were unaware of the limitations of the davit crane.

What did they learn?

Implement regular and ongoing training programs for both subcontractors and in-house employees, recognising that many subcontractors have long-term engagements.

Prioritise clear and open communication channels to facilitate information sharing and prevent misunderstandings.

Recognise the significance of every component within an operation and ensure that all aspects are given due attention and consideration.

Enhance procedures for collaborating with subcontractors to ensure effective coordination and execution of tasks.

Ask yourself or your crew

What was the potential severity of this incident?

How can something like this happen here?

How can we ensure that all team members fully understand and implement lockout/tagout procedures in our work environment?

What steps can we take to enhance the safety of lifting operations in offshore wind operations?

A subcontractor at a wind turbine generator (WTG) accidentally triggered the emergency brake during a lifting operation, causing three lift bags to fall into the sea. This incident occurred due to a lack of proper training, absence of lockout/tagout (LOTO) procedures, and insufficient focus on lifting operations in the risk assessment and method statement (RAMS). Additionally, there was a missing policy for ongoing training of long-term subcontractors and a lack of a pre-job briefing on the limitations of the davit crane.