-

What happened?

An LPG carrier vessel was alongside a terminal preparing for a scheduled LPG loading activity.

After the LPG carrier was secured, one of the aft mooring lines (aft breast line) that connected to the facility mooring hook parted.

Infield Support Vessels (tugs) were used to hold the vessel against the facility fenders to prevent movement.

The vessel was safely unmoored from the facility.

No one was injured. There was no damage to the LPG carrier or the terminal.

-

Why did it happen?

The mooring line parted at a load of 23 tonnes / 50,706 lbs (despite having a certified capacity of 46 tonnes / 101,413 lbs) due to:

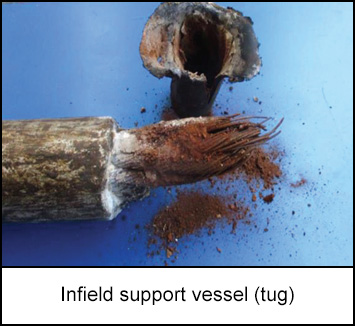

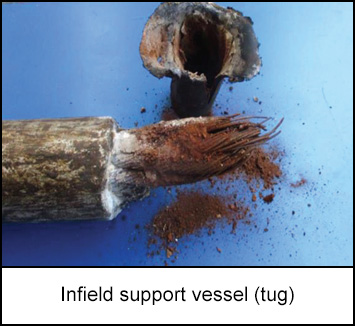

- poor condition (corrosion) of wire mooring lines provided by the LPG carrier, and

- insufficient assurance of mooring gear.

-

What did they learn?

Ensure assurance processes are in place for mooring gear.

Establish Line of Fire exclusion zones when conducting mooring activities.

-

Ask yourself or your crew

Are mooring activities conducted at your site? Are you aware of the risks involved in handling mooring equipment? Do you know the danger areas? Do you and your co-workers keep well clear?

Do you check mooring equipment prior to use in mooring activities?

What assurance process are in place for mooring gear? Who conducts them? When? What should be considered?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

An LPG carrier vessel was alongside a terminal preparing for a scheduled LPG loading activity.

After the LPG carrier was secured, one of the aft mooring lines (aft breast line) that connected to the facility mooring hook parted.

Infield Support Vessels (tugs) were used to hold the vessel against the facility fenders to prevent movement.

The vessel was safely unmoored from the facility.

No one was injured. There was no damage to the LPG carrier or the terminal.

Why did it happen?

The mooring line parted at a load of 23 tonnes / 50,706 lbs (despite having a certified capacity of 46 tonnes / 101,413 lbs) due to:

- poor condition (corrosion) of wire mooring lines provided by the LPG carrier, and

- insufficient assurance of mooring gear.

What did they learn?

Ensure assurance processes are in place for mooring gear.

Establish Line of Fire exclusion zones when conducting mooring activities.

Ask yourself or your crew

Are mooring activities conducted at your site? Are you aware of the risks involved in handling mooring equipment? Do you know the danger areas? Do you and your co-workers keep well clear?

Do you check mooring equipment prior to use in mooring activities?

What assurance process are in place for mooring gear? Who conducts them? When? What should be considered?

A liquefied petroleum gas (LPG) carrier vessel experienced a parted aft mooring line while preparing for loading at a terminal. Tugs held the vessel in place, allowing it to be safely unmoored without injuries or damage.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/operating-a-vessel-person-in-line-of-fire-leb-toolbox