-

What happened?

Two floorhands were using the tugger to pick up a joint of heavyweight drill pipe (HWDP).

One worker operated the controls lifting the joint, slowing down as the bottom crested the V-door to prevent swing.

Another worker used his arm to guide the HWDP to the mousehole as it was raised above the floor and as he was about to remove the thread protector, the HWDP dropped to the floor and began to fall toward the driller’s controls.

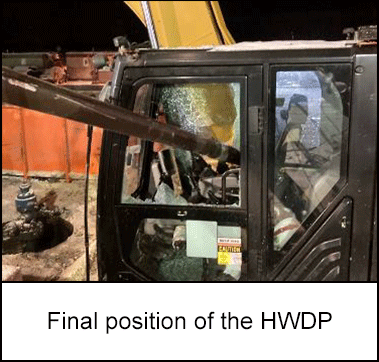

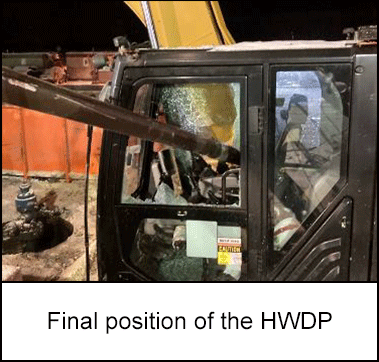

The top of the pipe struck the doghouse and bounced bottom up, throwing the worker into the steam manifold. As the pipe slid down the doghouse, it fell through the railing, and across the mud tanks missing a third worker. The HWDP smashed through the door of the track hoe and the operator threw himself to the front of the cab to avoid being struck.

-

Why did it happen?

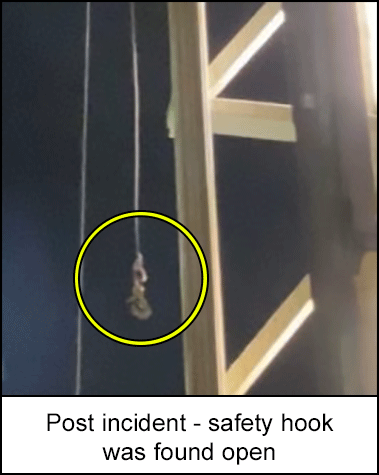

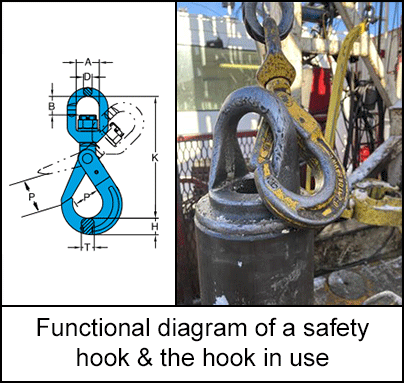

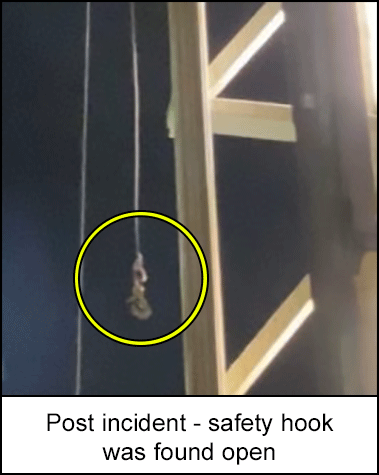

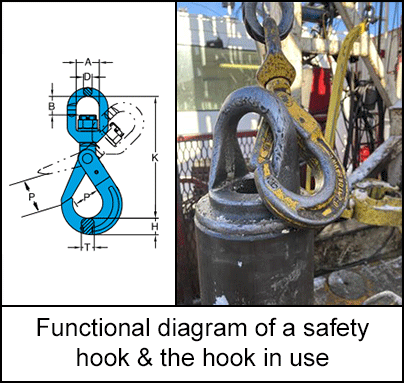

- The self-locking hook was not properly connected to nubbin, possibly due to side loading.

- The drill pipe traveled over 20 meters from well center to penetrate the cab of the track hoe.

-

What did they learn?

- The self-locking hook was removed from service and sent for testing. It passed inspection with no evidence of excessive wear, damage or manufacturers defects. It appears to have been fully functional at the time of testing and inspection.

- Tension should be placed on the tugger line when taking up slack and positioning the self-locking hook, so it holds the weight in the throat.

- There should be no equipment or cables that could become entangled while the rotary is engaged when the driller's controls are unattended.

- When attaching the self-locking hook to the nubbin, ensure it is closed and latched.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Two floorhands were using the tugger to pick up a joint of heavyweight drill pipe (HWDP).

One worker operated the controls lifting the joint, slowing down as the bottom crested the V-door to prevent swing.

Another worker used his arm to guide the HWDP to the mousehole as it was raised above the floor and as he was about to remove the thread protector, the HWDP dropped to the floor and began to fall toward the driller’s controls.

The top of the pipe struck the doghouse and bounced bottom up, throwing the worker into the steam manifold. As the pipe slid down the doghouse, it fell through the railing, and across the mud tanks missing a third worker. The HWDP smashed through the door of the track hoe and the operator threw himself to the front of the cab to avoid being struck.

Why did it happen?

- The self-locking hook was not properly connected to nubbin, possibly due to side loading.

- The drill pipe traveled over 20 meters from well center to penetrate the cab of the track hoe.

What did they learn?

- The self-locking hook was removed from service and sent for testing. It passed inspection with no evidence of excessive wear, damage or manufacturers defects. It appears to have been fully functional at the time of testing and inspection.

- Tension should be placed on the tugger line when taking up slack and positioning the self-locking hook, so it holds the weight in the throat.

- There should be no equipment or cables that could become entangled while the rotary is engaged when the driller's controls are unattended.

- When attaching the self-locking hook to the nubbin, ensure it is closed and latched.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

While using a tugger, two workers attempted to lift a joint of heavyweight drill pipe (HWDP). As one worker controlled the lift, the other guided the pipe towards the mousehole. However, the pipe unexpectedly dropped, causing it to hit the doghouse, slide through the railing, and narrowly miss a third worker. It then crashed through the track hoe's door, prompting the operator to quickly move away to avoid getting hit.

Original material courtesy of Energy Safety Canada

External resources:

Microlearning | Line of Fire - video

Dropped Objects Best Practice

Dropped Objects Microlearning Video

Energy Safety Canada has partnered with DROPS (DropsOnline.org) in the establishment of a Canadian Chapter. To become a member, review the Terms of Reference on the Canadian Chapter DROPS website and send an email to express your interest.