-

What happened?

During up-ending pre-assembly tasks on a turbine tower sections, a team of technicians were in the process of de-mobilising and leaving the working area.

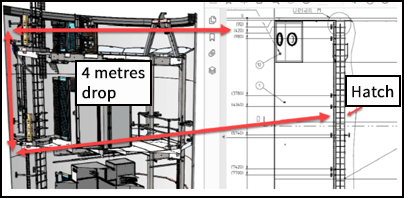

As they climbed down the tower, a working under suspended load (WUSL) camera fell from inside a personal bag.

The 5 kg (11 lbs) camera fell approximately 4 metres (13 ft) before striking the rear of the safety helmet of a technician on the same ladder direction.

The injured person (IP) was able to finish their descent to the platform entrance, where they reported to other team members that they felt sick and felt pain in their jaw.

After being advised by colleagues to sit down as a precaution, the IP was assessed by medical staff and signed off work for 7 days.

-

Why did it happen?

The supervisors instructed the technicians to remove the camera and brackets from the tower sections as they completed each up-ending task, which is a deviation from the approved work instruction in the installation manual.

The technicians deviated from the approved installation manual by removing the cameras and brackets without the use of the service lift.

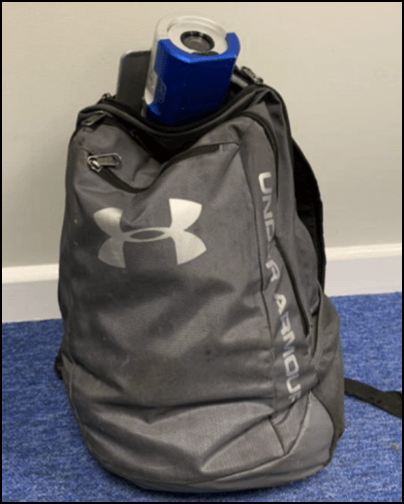

The team did not have access to approved lifting bags, resulting in the camera and brackets being placed in personal backpacks which were unsuitable for the task.

The technician stood above the injured person (IP) on the ladder, exposing the technician below to a drop hazard. Urgency to finish the task and fatigue after 14+ hours at work caused carelessness when leaving the wind turbine.

-

What did they learn?

Verify that all the materials required for carrying out the task safely are available prior to starting the activity (e.g. hauling kits, rope bag, lifting bags etc.).

Ensure that the management and technicians are aware of the correct standards, policies, and administration controls and that they are following them.

Complete site-wide fatigue assessment and consider how frequently teams are taking breaks. Personnel should not be allowed to work longer than 12-hour shifts.

During site inductions, personnel should be clearly instructed not to climb with any additional equipment or have multiple personnel on one ladder section at any one time. This should also be listed as a site rule.

-

Ask yourself or your crew

How can we prevent something like this from happening here?

How do you verify that all the necessary equipment is available before you start a task? What should you do if some/all the equipment is unavailable?

What measures do we have in place to assess fatigue and ensure personnel is taking breaks?

What should you do if you find yourself rushing and compromising safety to meet deadlines?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

During up-ending pre-assembly tasks on a turbine tower sections, a team of technicians were in the process of de-mobilising and leaving the working area. As they climbed down the tower, a working under suspended load (WUSL) camera fell from inside a personal bag. The camera fell approximately 4 metres (13 ft) before striking the rear of the safety helmet of a technician on the same ladder direction. The IP was assessed by medical staff and signed off work for 7 days.