-

What happened?

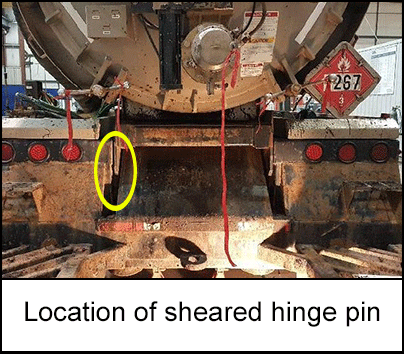

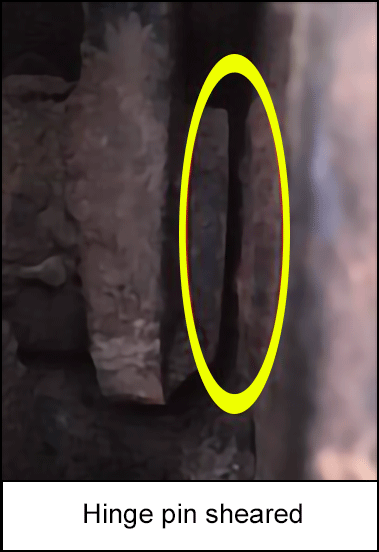

During a vacuum truck inspection the rear tank hinge pin was found to be sheared.

Under slightly different circumstances, this could have resulted in catastrophic failure of tank securement. Additional weight or the dumping of fluids could have led to the entire vessel falling off the body of the truck.

-

Why did it happen?

Road debris accumulation, fluid spillage, and location of hinge pin resulted in pin failure.

Contributing factors:

- Buildup of road debris in the hinge pin grease fittings and unprotected location of fittings.

- Inspection intervals and greasing frequency.

-

What did they learn?

- Company examined of all their vacuum trucks of similar design, to ensure hinge pins are inspected and greased.

- Company had engineer re-position of grease points to more protected location.

- Consider reviewing and, if necessary, revising service intervals. Company choose to revise theirs to every 250 hours.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

Published on 16/05/23

584 Views

During a vacuum truck inspection the rear tank hinge pin was found to be sheared. This could have resulted in catastrophic failure of tank securement. Additional weight or the dumping of fluids could have led to the entire vessel falling off the body of the truck.

Original material courtesy of Energy Safety Canada